Water transport characterization and modelling in porous building materials treated with a water repellent

Contact: Daphne Guilbert

Moisture is by far the main cause of deterioration of porous building materials as it facilitates processes as frost weathering, salt crystallization and biocolonization. In wall assemblies, the amount of moisture originating from wind driven rain can be minimalized by applying a water repellent product, mitigating the risk for degradation and improving thermal insulation. The application of a water repellent results in the deposition of a nanometric hydrophobic layer on the outer pore walls without drastically changing the diameter of the pores. Because of the high contact angle between water and the hydrophobic layer, absorption of wind driven rain is highly reduced, ideally to zero. In the meantime, drying of the porous material is still possible through water vapour transport. In reality, however, the efficacy of a water repellent treatment depends on many factors (e.g. cavities, cracks, fouling, material dampness and salts), which results in sometimes unsatisfying results and even acceleration of deterioration after the treatment. Therefore, it is important to fully investigate and understand a wall assembly before applying a water repellent product. For this, Heat-Air-Moisture simulations (HAM) are often used to assess the moisture content in wall assemblies, but the generic implementation of a water repellent layer in these models is currently limited by the lack of detailed material characteristics.

In this project, the efficacy of a standard water repellent treatment on different types of porous building materials (natural stone, brick, mortar) is studied by laboratory experiments in combination with onsite monitoring of test walls. Using the laboratory experiments, detailed information on water retention and transport in a treated material can be assessed for different environmental circumstances and applications methods. These experiments give more insight in the working of a water repellent treatment and on how to define hydrophobic layer in HAM-simulation software. The onsite monitoring of the test walls will be used to evaluate the defined hydrophobic layer using realistic weather data of weather stations close by the test walls. The goal is to understand how a hydrophobic layer should be properly implemented in HAM software so that the efficacy and the effects of a water repellent treatment better can be estimated before application.

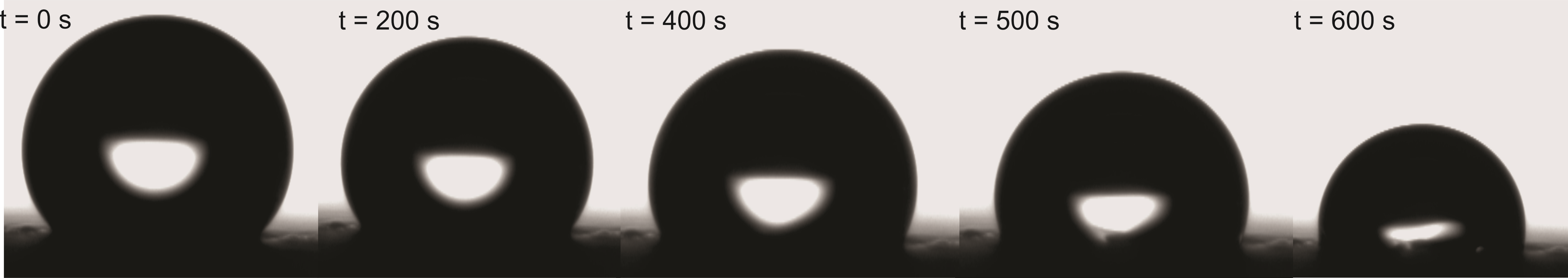

FIGURE: Evolution of the contact angle between a drop of water and a water repellent surface over 10 minutes.